Laser cutting has emerged as an accessible and exciting hobby that allows enthusiasts to transform digital designs into tangible creations. Whether you’re looking to craft intricate jewelry, personalized home décor, or even functional prototypes, the laser cutter can unlock endless creative possibilities. In this comprehensive blog post, we’ll explore what you need to begin, the diverse projects you can undertake, important safety guidelines, the environmental requirements for your workspace, and an overview of various types of laser cutters, including what each type is best suited for—and what it isn’t.

1. Understanding Laser Cutting

Before diving into the technical details, it’s important to understand what laser cutting entails. Essentially, laser cutting uses a focused beam of light to cut, engrave, or etch materials. The precision and versatility of the laser make it ideal for a wide range of applications, from delicate paper art to robust acrylic sign-making.

1.1 How It Works

The laser emits a high-powered beam that is directed at the material, melting, burning, or vaporizing the substance along a pre-defined path. The computer-controlled system interprets your digital designs and guides the laser head, ensuring each cut or engraving is executed with exact accuracy.

1.2 Why It’s a Great Hobby

Laser cutting is not only a fun way to explore creative design, but it also bridges the gap between traditional crafts and modern technology. With a little technical know-how, you can move from concept to creation in just a few hours. Moreover, the learning curve, while steep at first, rewards persistence with the satisfaction of producing professional-quality work at home.

2. Getting Started: Essential Tools and Materials

Starting out in laser cutting requires a mix of technical equipment, software knowledge, and a safe workspace. Here’s a detailed guide to what you need:

2.1 The Laser Cutter

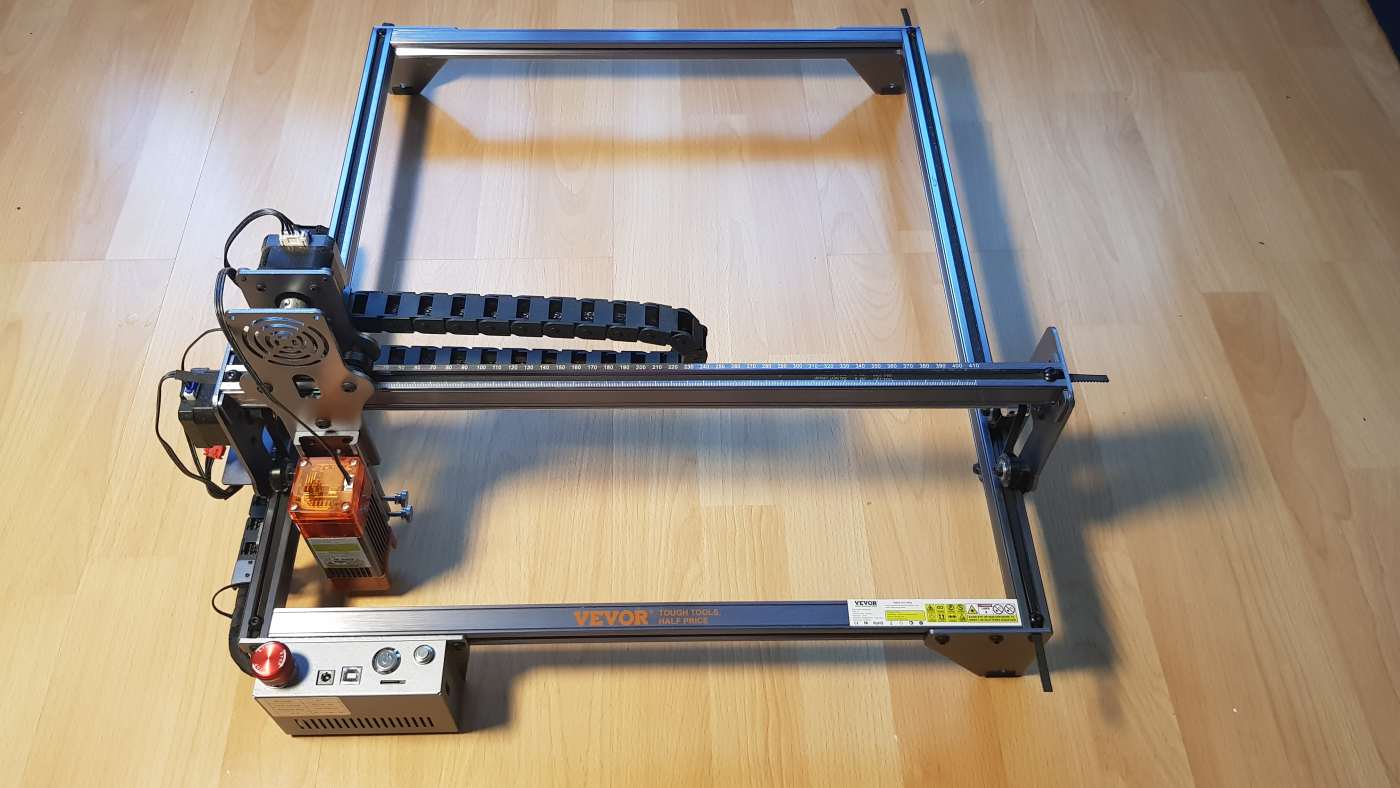

At the heart of your hobby lies the laser cutter itself. There are several models available, each designed for different budgets and project types.

- Desktop Laser Cutters: Ideal for hobbyists, these machines are compact and designed for home or small studio use. They can typically cut materials like wood, acrylic, and fabric. However, they might struggle with thicker or denser materials.

- CO2 Laser Cutters: Popular for their versatility, CO2 lasers are well-suited for non-metal materials. They provide clean cuts and can handle larger sheets of material, but require a bit more space and investment.

- Fiber Lasers: Although more expensive and typically used for industrial applications, fiber lasers excel in engraving and cutting metals. They are less common for hobbyists due to their cost and maintenance needs.

When choosing a laser cutter, consider your budget, the materials you plan to work with, and the space available in your home or workshop.

2.2 Software for Design and Operation

To bring your creative visions to life, you’ll need design software to create or modify vector files. Popular options include:

- Adobe Illustrator: A professional-grade tool that offers extensive features for graphic design.

- Inkscape: A free, open-source alternative that supports vector editing and is widely used in the laser cutting community.

- CorelDRAW: Another professional option that many laser cutting enthusiasts prefer due to its user-friendly interface and robust feature set.

Alongside design software, laser cutters often come with proprietary control software that translates your designs into instructions the machine can follow.

2.3 Materials and Supplies

The choice of materials is crucial in laser cutting. Here are some common options:

- Wood: Plywood, MDF, and hardwood are popular for making signs, puzzles, and decorative items.

- Acrylic: Ideal for both cutting and engraving, acrylic is widely used for display pieces and lighting fixtures.

- Fabric: Certain fabrics can be laser cut for custom clothing, accessories, or home décor items.

- Paper and Cardboard: Great for prototyping or creating intricate paper art.

- Metals: For those using fiber lasers, metals like stainless steel and aluminum offer new creative avenues.

2.4 Additional Accessories

Investing in accessories can enhance your workflow and ensure precision:

- Air Assist System: This helps clear smoke and debris from the cut, improving both quality and safety.

- Exhaust System: Vital for venting fumes, particularly when working with materials that produce hazardous byproducts.

- Calibration Tools: These help maintain the accuracy of your machine over time.

- Protective Gear: Safety goggles, gloves, and fire extinguishers are essential in any laser cutting setup.

3. What You Can Create with a Laser Cutter

Laser cutters open up a myriad of creative possibilities. Here are some project ideas to spark your imagination:

3.1 Home Décor and Furniture

From custom wall art to intricately designed lampshades, laser cutters enable you to design bespoke home décor. You can also create small pieces of furniture or decorative panels that add a unique touch to your living space.

3.2 Personalized Gifts and Accessories

Imagine crafting personalized gifts for friends and family—custom keychains, engraved picture frames, or even bespoke jewelry. These projects not only showcase your creativity but also have a personal touch that mass-produced items can’t match.

3.3 Prototyping and Engineering Projects

For those interested in engineering or robotics, laser cutters can be used to create prototypes, enclosures, and parts for DIY electronics projects. Their precision makes them ideal for creating functional and aesthetically pleasing components.

3.4 Art and Design

Artists can leverage laser cutting to explore new mediums and techniques. Whether it’s intricate paper art or large-scale installations, the machine’s precision allows for a level of detail that would be impossible by hand.

3.5 Educational Tools and Models

Educators and students alike can use laser cutters to create educational models. These can range from historical replicas and architectural models to interactive learning tools that make complex concepts more tangible.

4. Safety Guidelines and Best Practices

While laser cutting is an exciting and innovative hobby, it also comes with risks if not handled properly. Here are some essential safety guidelines:

4.1 Personal Protective Equipment (PPE)

- Safety Goggles: Always wear appropriate laser safety goggles to protect your eyes from harmful laser emissions.

- Gloves: When handling materials post-cutting, especially if they are sharp or heated, wear protective gloves.

- Respirators or Masks: Some materials can produce toxic fumes; always use a respirator or mask if you’re working with potentially hazardous materials.

4.2 Workspace Safety

- Ventilation: Ensure your workspace is well-ventilated. A good exhaust system is necessary to remove smoke, fumes, and airborne particulates.

- Fire Safety: Keep a fire extinguisher nearby. Laser cutting, particularly with flammable materials like wood or paper, can pose a fire risk if not monitored.

- Stable Setup: Make sure the laser cutter is set up on a stable, non-flammable surface. Secure all cables and ensure that the area around the machine is clear of obstructions.

4.3 Operational Guidelines

- Supervision: Never leave the laser cutter unattended while it’s in operation. This is crucial to quickly address any issues that may arise.

- Regular Maintenance: Keep your machine well-maintained. Clean the lens, check for debris, and ensure that all moving parts are functioning correctly.

- Software Safety: Before starting any new project, run simulations or test cuts on scrap material to ensure that your settings are safe and effective.

4.4 Handling Materials Safely

- Material Knowledge: Understand the properties of the materials you’re working with. Some materials can emit toxic fumes or may even catch fire when exposed to a laser.

- Post-Processing: Some laser-cut materials require additional processing, such as sanding or chemical treatments. Always handle these with appropriate safety gear and in a controlled environment.

5. Environmental Requirements for Your Workspace

Creating a safe and efficient workspace is vital for your success with laser cutting. Here are the key environmental factors to consider:

5.1 Adequate Space

- Size of the Machine: Ensure you have enough room for both the laser cutter and the materials you plan to work with. Desktop machines require less space, but industrial or larger hobbyist models may need dedicated areas.

- Workspace Layout: Plan your workspace so that there is a clear area around the machine for safe movement. Keep tools and materials organized and within reach.

5.2 Ventilation and Air Quality

- Exhaust System: A high-quality exhaust system is non-negotiable, especially when working with materials that produce hazardous fumes.

- Air Filters: Consider using additional air filters to maintain a clean environment, especially if you plan to work on projects for extended periods.

5.3 Fire Safety Measures

- Non-Flammable Surfaces: Place your machine on a surface that resists heat and fire.

- Emergency Plan: Have a clear emergency plan in place. Know the location of fire exits, and ensure that everyone in your workspace is aware of the safety protocols.

5.4 Lighting and Accessibility

- Proper Lighting: Ensure your workspace is well-lit. This not only improves safety but also enhances the precision of your design work.

- Accessibility: Keep your workspace accessible, particularly if you plan to work on larger projects or if multiple people will be using the machine.

6. Types of Laser Cutters: Which One Is Right for You?

There is a wide variety of laser cutters on the market, each suited to different materials, budgets, and project requirements. Here’s an overview to help you decide:

6.1 Desktop Laser Cutters

- Best For: Beginners, hobbyists, and small-scale projects.

- Advantages: Compact, affordable, and easy to use.

- Limitations: Often have a smaller work area and less power, making them unsuitable for thicker or denser materials.

6.2 CO2 Laser Cutters

- Best For: Medium to large-scale projects, particularly with non-metal materials such as wood, acrylic, and fabric.

- Advantages: Versatile, with a larger cutting area and greater power than most desktop models.

- Limitations: They require more space and a higher initial investment. Also, the maintenance and safety considerations are more demanding.

6.3 Fiber Laser Cutters

- Best For: Industrial use or hobbyists looking to work with metals and demanding precision tasks.

- Advantages: High precision, faster cutting speeds, and the ability to work with metals.

- Limitations: High cost, more complex maintenance, and they are generally not recommended for beginners or small workshops.

6.4 Hybrid Models

Some models combine the benefits of different systems, offering features that allow users to switch between cutting materials like wood and metal. These are often more expensive but can be a versatile option for those looking to explore a wider range of projects without needing multiple machines.

Conclusion

Embarking on a journey with laser cutting as a hobby opens a world of creative and practical possibilities. Whether you’re interested in crafting personalized gifts, designing home décor, or even building prototypes, understanding the basics—from choosing the right machine and materials to adhering to safety protocols—is essential. A well-planned workspace, proper maintenance, and an awareness of the specific demands of your chosen projects will ensure your hobby is both enjoyable and safe.

By starting with a desktop or CO2 laser cutter, you can gradually expand your skills and move towards more complex projects. Always remember to prioritize safety by using appropriate protective gear, maintaining proper ventilation, and being mindful of the fire risks inherent in working with lasers and combustible materials. As you progress, you may find that your interest in laser cutting evolves into a serious craft or even a small business venture, proving that with a bit of dedication and careful planning, the sky is the limit.

Laser cutting is not just a tool—it’s a gateway to a blend of art, technology, and innovation. Whether you’re a seasoned maker or just starting out, the process of designing, cutting, and finishing your projects will continually challenge you and reward you with tangible, satisfying results. So gather your tools, set up your workspace, and start exploring the endless possibilities that laser cutting has to offer.

With the right approach and an eagerness to learn, you can transform your creative ideas into reality, one laser beam at a time.

1 Response

[…] Lasercutter ist ein computergesteuertes Werkzeug, das mithilfe von Laserstrahlen Materialien wie Holz, Acryl, Stoff und sogar Metall präzise […]